Brief introduction of PDC and PDC bit history

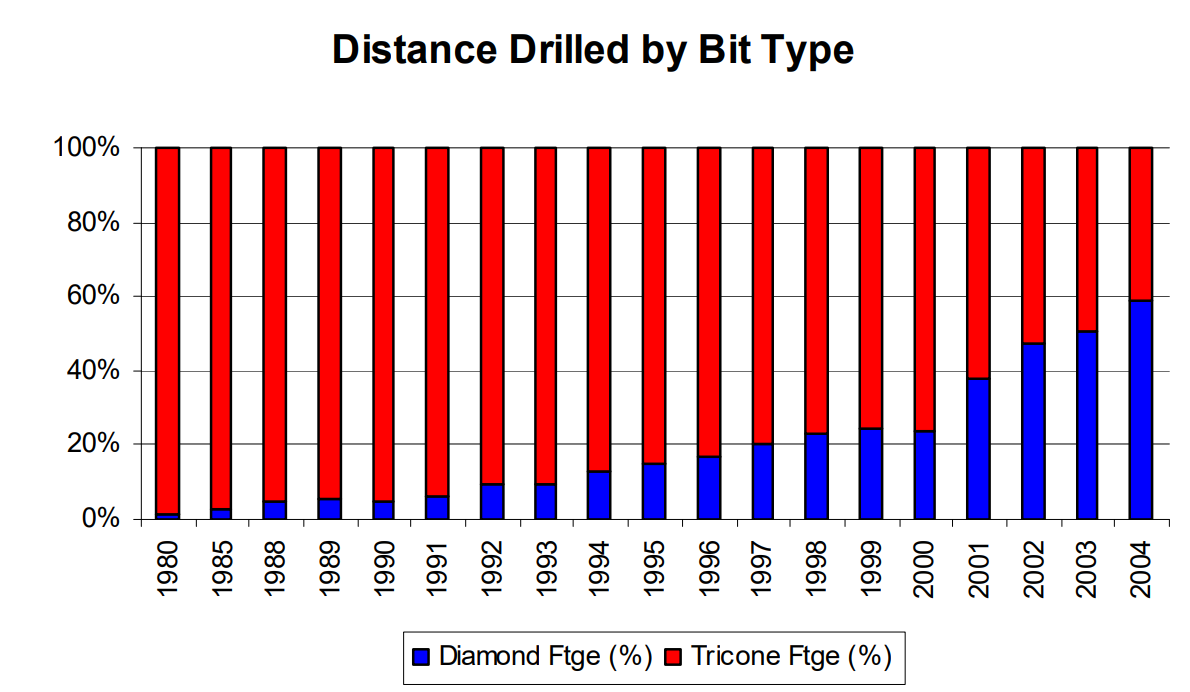

Polycrystalline diamond compact (PDC) and PDC drill bits have been introduced to the market for several decades. During this long time PDC cutter and PDC drill bit have experienced many setbacks in their early stages, also experienced great development. Slowly but finally, PDC bits gradually replaced cone bits with continuous improvements in PDC cutter, bit stability, and bit hydraulic structure. PDC bits now occupy more than 90% of the total drilling footage in the world.

PDC Cutter was invented firstly by General Electric (GE) in 1971. The first PDC Cutters for the oil and gas industry was done in 1973 and with 3 years of experimental and field testing, it is introduced commercially in 1976 after it is proven much more efficient than crushing actions of carbide button bits.

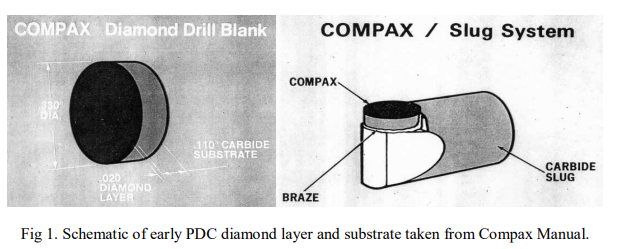

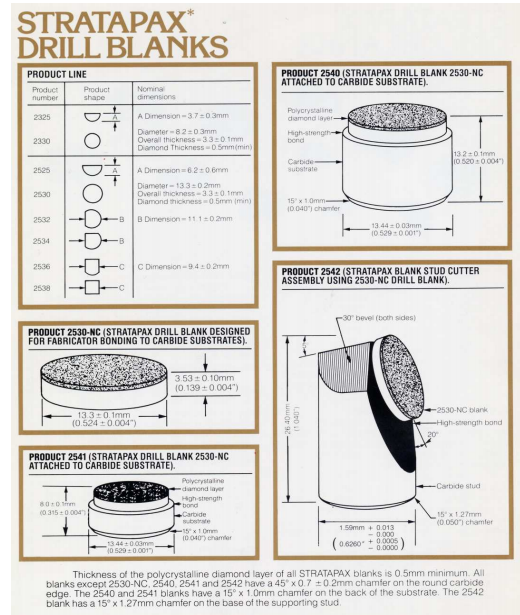

In the early time, the PDC cutter’s structure is like this: a carbide round tip, ( diameter 8.38mm, thickness 2.8mm), and a diamond layer ( thickness 0.5mm without chamfer on the surface). At that time, there was also a Compax "slug system" PDC cutter. The structure of this cutter was like this: the PDC compax weld to the cemented carbide slug so that it could be easier to install on the steel body drill bit, thereby bringing greater convenience to the drill bit designer.

In 1973, GE has tested its early PDC bit in a well in the King Ranch area of southern Texas. During the test drilling process, the cleaning problem of the bit was considered to exist. Three teeth failed at the brazed joint, and two other teeth broke together with the tungsten carbide part. Later, the company tested a second drill bit in the Hudson area of Colorado. This drill bit has improved the hydraulic structure for the cleaning problem. The bit has achieved better performance in sandstone-shale formations with fast drilling speed. But there are several deviations from the planned borehole trajectory during drilling, and a small amount of PDC cutters loss still occurred due to the brazing connection.

In April 1974, a third drill bit was tested in the San Juan area of Utah, USA. This bit has improved the tooth structure and bit shape. The bit replaced the steel body cone bits in the adjacent well, but the nozzle dropped and the bit was damaged. At that time, it was considered to occur near the end of drilling for a hard formation, or a problem caused by the falling nozzle.

From 1974 to 1976, various drill bit companies and entrepreneurs evaluated various improvements in PDC cutter. Many existing problems were focused on research. Such research results were organically integrated into the Stratapax PDC teeth, launched by GE in December 1976.

The name change from Compax to Stratapax helped to eliminate the confusion in the bit industry between bits with tungsten carbide compacts, and diamond Compax.

In the mid-90s, people began to widely use chamfering technology on PDC cutting teeth, the multi-chamfer technology was adopted in the form of a patent in 1995. If the chamfering technology is applied correctly, the fracture resistance of the PDC cutting teeth can be increased by 100%.

In the 1980s, both GE Company (USA) and Sumitomo Company ( Japan) studied the removal of cobalt from the working surface of PDC teeth to improve the working performance of the teeth. But they did not achieve commercial success. A technology was later re-developed and patented by Hycalog(USA). It was proved that if the metal material can be removed from the grain gap, the thermal stability of the PDC teeth will be greatly improved so that the bit can drill better in harder and more abrasive formations. This cobalt removal technology improves the wear resistance of PDC teeth in highly abrasive hard rock formations and further broadens the application range of PDC bits.

Beginning in 2000, the application of PDC bits has expanded rapidly. The formations that could not be drilled with PDC bits have gradually become able to be drilled economically and reliably with PDC drill bits.

As of 2004, in the drill bit industry, the market revenue of PDC drill bits occupied about 50%, and the drilling distance reached nearly 60%. This growth continues to this day. Almost all currently used in North American drilling applications are PDC bits.

In short, since it was launched in the 70s and experienced its initial slow growth, PDC cutters have gradually promoted the continuous development of the drill bit industry for oil and gas exploration and drilling. The impact of PDC technology on the drilling industry is huge.

New entrants in the market of high-quality PDC cutting teeth, as well as major drill companies, continue to lead the reform and innovation of Innovative materials and production processes so that the performance of PDC cutting teeth and PDC drill bits can be continuously improved.